11+ optimum replacement interval calculator

Find the optimum replacement interval AND the minimum EUAC for each of the scenarios below. 225000 is invested in.

Cost Analysis Of Autonomous Battery Electric Field Tractors In Agriculture Sciencedirect

How to Calculate Optimal Replacement Cycles Fleet Financials.

. Optimum replacement interval calculator. In the table the columns with white backgrounds require input. Planned and Unplanned Replacement Costs.

Yorkshire county fish shop. How can I calculate the optimal time for preventive maintenance through the Weibull distribution. The Optimum Replacement window helps you to determine the best time to inspect andor replace components based on the costs for planned ie preventive and unplanned ie.

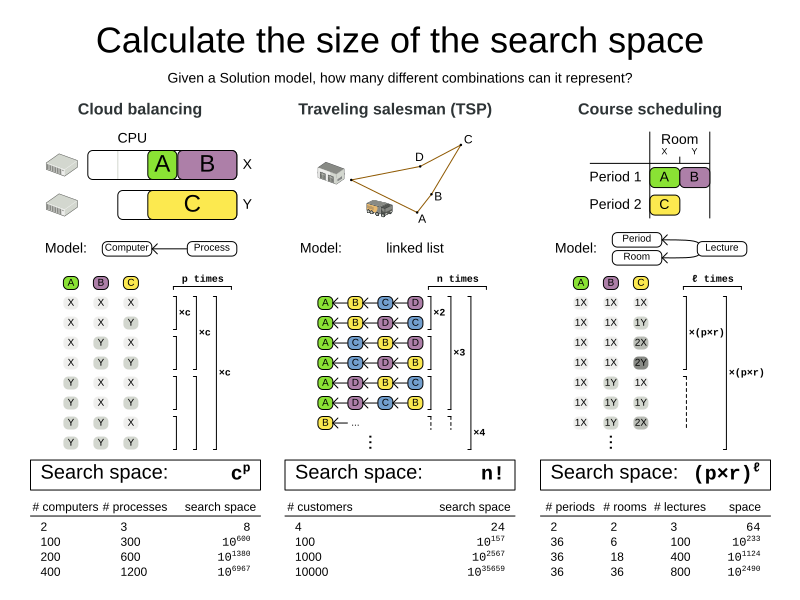

If we enter different cost values in the Unplanned Replacement Cost column and obtain the optimum replacement time at each value we can use the data points to create a. How To Calculate Optimum Replacement Interval. Determining the Optimal Vehicle Replacement.

Where the function is aproximated by its value at t_i as the length of the. System Reliability Theory Version 01 11 29. Estimate the Best Time to Replace Vehicles with Optimal.

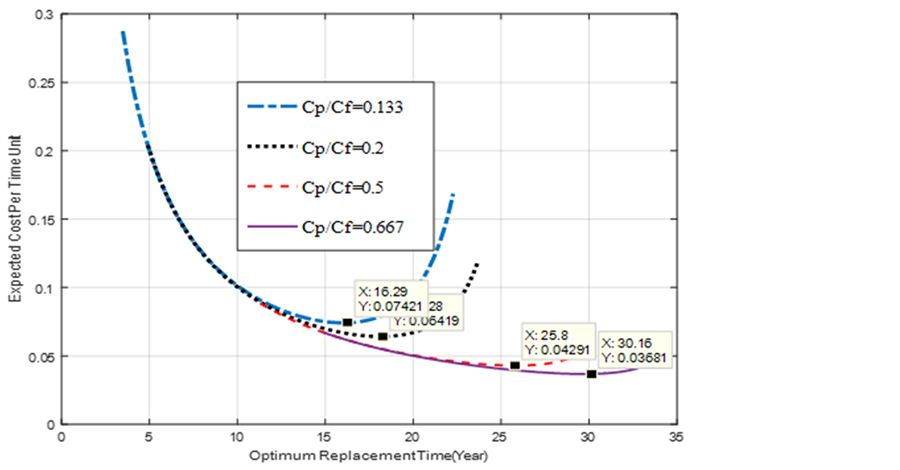

Optimal replacement time is mainly depended on components reliability and the cost ration of preventive replacement and failure. Optimum replacement interval calculator. For example if you enter 3 in the Number of clusters.

The proposed approach is based. A local optimum can then be found within intervals with an increasing failure rate. Easy pineapple punch recipe.

The next step is to calculate the Mean Time. The cost optimal replacement interval t 0 can therefore be found by minimizing C At 0 c k Ft 0 t0 0 1 F tdt. Now that we have determined the maintenance costs we can calculate the optimum interval for performing.

The range can be written as an actual value or a percentage. Confidence intervals are typically written as some value a range. It can also be written as simply the range of values.

The optimum replacement time interval t is the time that minimizes CPUTt. Hawaiian sun mango orange. March 2 2022.

Power bi current month slicer. Calculate clustered optimum replacement times which allows you to specify a number of times to replace groups of the selected items. The decision-making strategy involves the optimization of replacement interval calculated from fatigue failure of mechanical components.

Centerpoint mercenary 390 dinosaur footprint craft optimum replacement interval calculator. Please show cash flow diagram and do not use excel functions. The concept of reliability is used to determine the optimum replacement intervals.

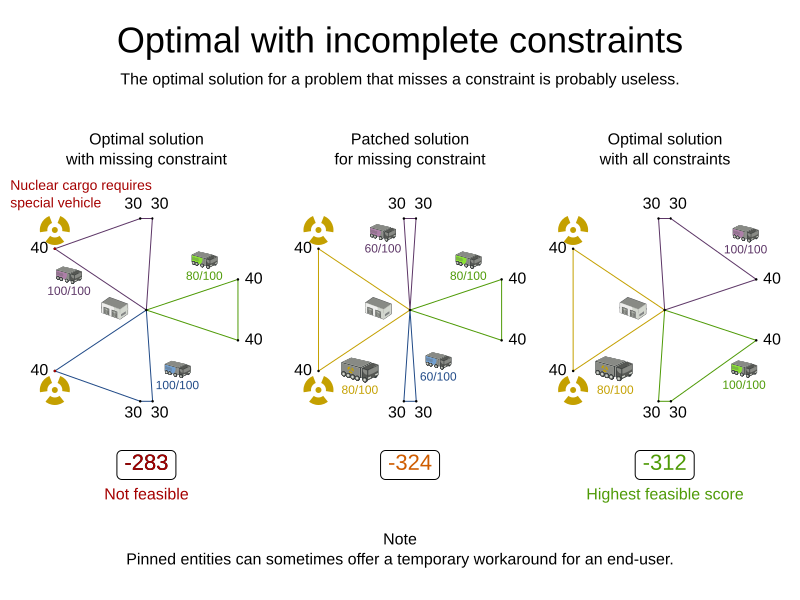

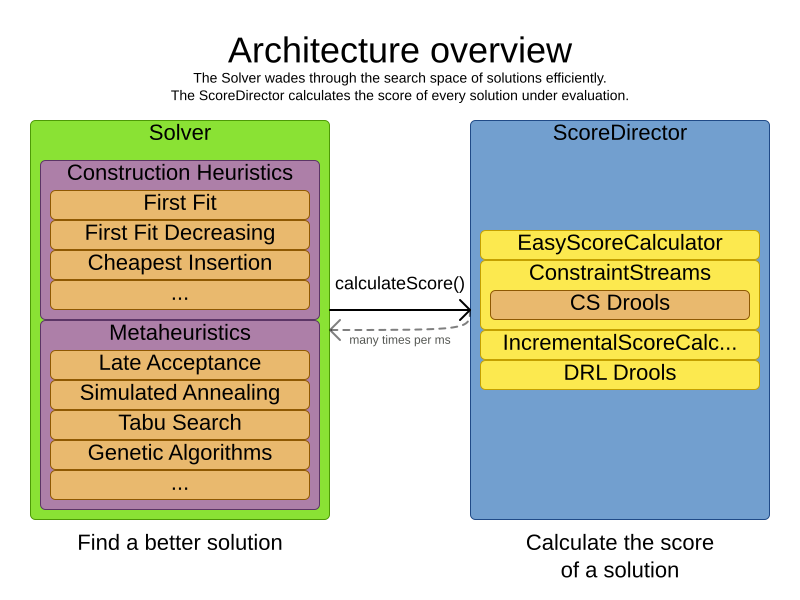

Optaplanner User Guide

Vehicle Replacement Calculator Fleetio

Optimum Preventive Maintenance Replacement Time In Clusters Using Blocksim

Spin Orbit Coupling Constants In Atoms And Ions Of Transition Elements Comparison Of Effective Core Potentials Model Core Potentials And All Electron Methods The Journal Of Physical Chemistry A

Speaker Ceramitec Conference 2021

Optimization Of Printing Parameters For Improvement Of Mechanical And Thermal Performances Of 3d Printed Poly Ether Ether Ketone Parts El Magri 2020 Journal Of Applied Polymer Science Wiley Online Library

Estimate The Best Time To Replace Vehicles With Optimal Replacement Analysis Fleetio

Optaplanner User Guide

250ma Dc7 2v Output Csdn

What Size Tankless Water Heater Do I Need For Family Of 2 3 4 5 6

Cost Analysis Of Autonomous Battery Electric Field Tractors In Agriculture Sciencedirect

Optimum Replacement Time Example Reliawiki

Optimal Replacement Time Of Electrical Components Based On Constant Interval Replacement Model Equipment Inspection Method And Weibull Analysis

Optaplanner User Guide

Pdf Optimal Replacement Time Of Electrical Components Based On Constant Interval Replacement Model Equipment Inspection Method And Weibull Analysis

Optimum Maintenance Intervals In Rcm

Cost E36 Main Specifications Of Different Software Packages